Solar tracker

Overview

This is the solar array I built for my parents in Kingman, AZ. Perhaps the information here will be useful for anyone else looking to embark on a similar project. There's lots of things I would have done differently and lots of things that could use improvement, but that's how any project goes right?

The goal was to roughly meet our average energy use of 700kWh/month with a grid-tie system. There's no point in generating excess, since our utility only applies it as a credit to future bills (and you pay to maintain connection anyways). I used the data here ![]() to predict the amount of sun we can expect for our area. Since we'd be tracking on one axis with the second manually adjustable, we can figure on average roughly 9 peak hours of sun per day. Sun electronics had some nice 200 watt Suntech panels for about $2.10/watt, and we decided to go with 12 of these for a total of 2.4kW. At 9 peak hours of sun, that gives us around 648kWh per month (not counting line and inverter losses, and heat degradation of the panels). That seemed to be a fair trade off, while maintaining a reasonable size. Multiple smaller trackers were also considered, but we have some space limitations as far as unshaded area of the yard goes and 2 separate trackers would have been difficult to fit in.

to predict the amount of sun we can expect for our area. Since we'd be tracking on one axis with the second manually adjustable, we can figure on average roughly 9 peak hours of sun per day. Sun electronics had some nice 200 watt Suntech panels for about $2.10/watt, and we decided to go with 12 of these for a total of 2.4kW. At 9 peak hours of sun, that gives us around 648kWh per month (not counting line and inverter losses, and heat degradation of the panels). That seemed to be a fair trade off, while maintaining a reasonable size. Multiple smaller trackers were also considered, but we have some space limitations as far as unshaded area of the yard goes and 2 separate trackers would have been difficult to fit in.

John Mieding of Mieding & Associates in Bullhead city deserves much of the credit for helping me finalize the CAD drawings into plans and engineering the structure such that it should withstand 90+mph winds that the building codes here require.

Sun electronics has a warehouse in Phoenix, so we were able to drive down and pick up the panels to save shipping costs. These are pretty good sized panels, weighing about 40lbs each.

The black box contains three bypass diodes for when the panel is in the nonconducting (in the shade). Each panel has 8 mounting points, which Suntech recommends you use for windy areas. The idea was to put bolts through the frame to hold each panel on. Looking back, I think it would have been better to design around I-beam or U-channel instead of square tubing, but neither were readily available at the time.

Hinge Construction

A solar tracker needs to pivot in two dimensions - one to account for the change in the sun's elevation and one for the daily movement. A "Polar mount" allows tracking of the daily movement with a single actuator, and as such is the method of choice for solar trackers. I originally was hoping to use a mount from an old C band satellite dish, but it quickly became apparent that wouldn't be strong enough for an array of this size. In the end I decided to fabricate one from scrap metal.

In fact almost all the material for this project was sourced from the local scrapyard. At the time, they were selling steel for 40c/lb which was a lot cheaper than buying it new (and some of what they had was in like-new condition anyways). Going through the scrap yard and looking for stuff was also great fun, and the design was constantly being tweaked to make use of the cheapest available materials. The main items were the 8" schedule 80 pipe that makes up the mast and the 5/8" steel plate that makes up the base and parts of the polar mount. That steel plate was very heavy and we had no way to move it around once it was loaded on the trailer. I used a torch to cut it into the necessary pieces without ever moving it off the trailer (thanks to Don Kay for letting us borrow that).

I was a little concerned about how well my little 220v MIG welder would penetrate this heavy steel, so I did some practice runs. I beveled about 1/4" off each edge and preheated the metal with a torch to around 400F.

It seems to penetrate pretty well though and after a few opinions from other welders, I decided it's probably good enough :-). I started by cutting out all the pieces from the 5/8" steel plate. You have to be pretty steady with the torch to get a decent cut. I used a piece of angle iron as a guide to keep a nice straight cut. It takes a long time to grind something this thick, so I had a lot of motivation to make clean cuts with the torch!

These guys will go between the base plate and the mast for additional support.

One more for a bit of a size reference...

One more of all the pieces together. The large square piece in the back will be the base, the long piece with rounded corners will be one of the endcaps, the two long, triangular pieces will be the frame mounts, and the 3 pieces in the front make up the base and sides of the polar mount.

Here you can see the polar mount coming together. That's a 2" hardened steel pin going in between - it took about 20 minutes to cut through it with a chopsaw. We had a local machine shop bore out the holes in each plate and cut a grease groove in the bearing surface. Although it really won't move much (this will be the hinge too allow for manual elevation adjustment), it's probably still a good idea to keep everything in good shape. There will be zerk fittings on top of each plate. The real trick here was trying to keep those plates perfectly perpendicular to the base (and parallel to each other) while welding them on. There's only a few thousands clearance between the bearing surfaces and that pin, so it's got to be pretty close. Actually it was kind of a big headache, and next time I'm sure it'd be better done with flange bearings bolted to the plates since they allow quite a bit of freedom in alignment.

Here's a few pictures of the welds going down on the polar mount assembly. Again, I beveled about 1/4" off each side of everything and preheated to around 400F with the torch to maximize penetration. In the end, there was lots of discoloration on the opposite side of the weld (which usually indicates decent penetration) so it was worth it.

And then 2 more welds on top of the root weld...

Now here's the hinge tube in between the plates. This will be on the north-south axis, and the array will track into and out of the picture. It's at about 40 degrees of elevation in the picture, so that's where it would be sometime in the spring or fall.

And now, these pieces get added to the hinge tube. That rod on the left is the other piece of that 2" steel pin I mentioned earlier. We had 2" holes bored through each of those endcaps, and the pin slides through and is welded in place. The whole array will then pivot on that pin.

Here's the endcap welded on. You can see the steel pin "tacked" in the far right.

And here it is all finished! You can see how the far right endcap is pulled in from the weld shrinkage is. The array frame will bolt to each of those flange bearings in the center. The flanges are built such that the bearing can pivot about 15 degrees each way, so they don't have to be aligned perfectly.

Frame & Mast

This is the frame to hold all the panels. It's mostly made out of 2" square steel tubing, and a little 115v MIG welder does this stuff very nicely. Above is a picture of it going together, before all the vertical braces were on.

The only shot I have of it completed is during painting. All together, I think it weighed around 500 lbs.

We set all the panels on to see how it would look and to mark where all the mounting holes should go.

And here's one looking from the underneath.

The last main piece was the mast and mounting plate. The same machine shop drilled the 1-1/4" holes that'll mount down to the J-bolts in the foundation. They had a CNC plasma cutter as well, so I had them do the large hole in the center too. It's cool how nice a cut that makes! I beveled the outside of the pipe about 1/4", preheated it all, and welded the heck out of it. There was really only room for the one root weld on the bottom, so I left it at that.

On top, I put 3 welds all around and then all 8 gussets over that. Each gusset was bevelled and preheated to improve weld penetration.

Here's the mount welded to the top. This is mounted in such a way that it'll face exactly true south when everything's bolted to the foundation. On top of the mount in the center, I welded a little 3/4" steel nipple to bring the wires through and screw a junction box onto.

That completes most of the main construction. Everything was sprayed with a black laquer paint to keep things looking nice and prevent rust. Next up is the foundation and inverter installation.

Foundation & Inverter

The hole needed to be about 5' deep by 3' square.

I welded the rebar cage all together since that seemed like the best way to keep everything in alignment. It was very rigid like this which helped keep all the bolts aligned - it was important to match the holes already drilled in the base plate, probably did that in the wrong order :)

We made the 2x4 jigs to hang the whole thing at the correct height. It was about 1.6 yards of concrete, mixed by hand in a small mixer. Threw a few large stones in there too.

Here's a shot of it almost full. We finished the top and then let it cure for a week before setting the tracker on it.

Here is the trench full of conduits. One is bringing DC power from the panels into the inverter, and one is bringing 120 VAC out to run the tracking motors and such. The 3rd one has a piece of coax I thought I might like to use for a camera. It's about a 150ft run, but the PV system runs at around 300 VDC so the resistance losses are pretty insignificant.

It all terminates at the side of the house. The inverter is mounted in the basement, so we were able to put the conduit straight through the wall into the inverter junction box.

Here's the inverter mounted. This is the Xantrex GT2.8 and so far it's worked very well.

This is the meter and AC disconnect switch. Although our utility allows net metering, they want a second meter to measure just what the PV system is generating. They then replace the main meter with a bi-directional unit that keeps track of how much has been used versus how much has been pushed back into the grid. The inverter outputs 240 VAC and is connected to that square D external disconnect. This is connected to the generation meter which is wired into the breaker panel like any other 240 V circuit. Next is raising the tracker and mounting all the panels.

Final Assembly & Raising

Our neighbor was kind enough to bring over his work truck on the weekend to assist in setting everything up on the foundation. The mast had to be lifted into place and bolted down, and then the frame mounted on top. We put tar on the bottom of the base to help protect it from the water. Not that 5/8" of steel is going to rust through anytime soon, but it's probably a good idea. :) One of the holes didn't quite fit over the bolt and had to be elongated by about 1/16" but other than that, everything went pretty smoothly.

The hinge tube and bearings were all mounted, so once the frame and everything was lifted into position, that 2" steel pin was slid in and held everything in place.

Next up was installing the panels. They don't weigh that much but they're bulky and not that easy to carry up a ladder. We used moving blankets as padding, and then slid them up the ladder and into place using ropes. There are 8 bolts that hold each panel in place. The holes in the panels are elliptical so you have a little room to move things around and get them all even.

Here's a view from the back. Notice the electric linear actuator; the original intention was to use that to drive the array. As it turned out, it wasn't really up to the job as this whole thing is pretty heavy. I think the biggest problem was the slop introduced by it. In windstorms, the array would wobble an uncomfortable amount because of the slop in the gears :-). The temporary solution was to replace it with a 2" steel pipe to lock the array in place in the noon-day position until I could come up with something more stout.

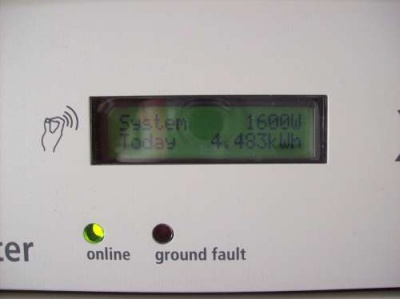

I had to take a picture of the inverter when it first powered up and came online. That actually ended up being the day before I had to go back to school, so the project halted here for a few months. The tracking controller and hydraulic actuator was added later.

Hydraulics

As mentioned previously, the electric actuator wasn't up to the task of moving the array. The necessary parts for a small hydraulic system can be had from surpluscenter.com for not much more than a larger electric actuator would have cost. Since there's very little slop in a hydraulic system and it's certainly plenty strong, we decided to go that route. The original intention was to use that big oil filter as a tank as recommended by a local hydraulic guy, however that didn't end up working...

Here is the whole setup. Using the filter as a tank didn't seem to work out very well... I could never get all the air out of it. When used as a tank, the oil level needs to rise up and down as the cylinder expands and contracts. It turns out need a bit of pressure to pull the oil through the filter element - gravity just won't do the trick, so the center of the filter was constantly being sucked too low and the outside overflowing. I ended up welding a small tank and screwing it to the top of the filter to keep it always full of oil. The pump is a small volume gear pump, and the pressure regulator is set to around 1000 psi. The blue rectangle on the right side is a double-acting solenoid. It's driven by two 115 VAC solenoids. Powering one drives the ram in while powering the other drives it out. On the outlet of the solenoid is a needle valve to adjust the speed of the ram. The goal here is a smooth, slow movement so it's tightened down a lot. This particular valve allows free flow in one direction, which caused a little bit of confusion initially :-)

This is the ram installed. It's a 20" stroke x 2" bore. The wires tied to it are connected to the limit switches. This allows the controller to determine when the array has reached the extent of it's travel.